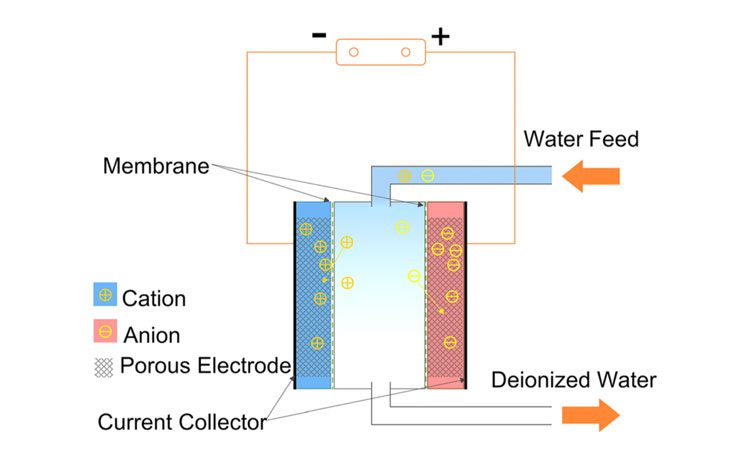

A deionizer is a device consisting of an anionic and a cationic column capable of producing ion-free, electrically conductive water of 1 μS. In the cation column, all cations including carbonate, sulfate, chloride, and silicate are removed. Other features of the Deionizer device include the following:

· Design of deionizer based on complete water analysis

· Cationic and anionic columns made of anti-acid 316 stainless steel or composite

· Repairable pipes made of C.V.P polypropylene

· Equipped with online PH meter device

· Has an electric conductivity meter and polyethylene tanks

Steps of producing ultra-pure water with a deionizer

Due to the use of pure water and the need to remove all waste materials and ions and organic matter in it, the process of producing pure water with a deionizer device includes several important steps, which are:

Removal of solid particles and heavy metals in water

In the first step, by passing water through activated carbon filters and sediment filters, heavy metals and insoluble solids with a size of more than one micron and water-soluble gases are removed. The water output from this step contains ions and salts. So it can’t be removed with activated carbon filters and sediment filters. Therefore, they enter the next stage after the deionizer device.

Removal of salts and ions by reverse osmosis

Reverse osmosis, which is one of the most practical methods in the production of pure water, has the ability to remove monovalent and polyvalent ions. In addition, this method can remove the insoluble solid particles left over from the previous step, which are greater than 0.0001 μm. Water passes through RO cartridges at the pressure of an electric pump, eventually removing up to 95% of the ions in the water. The output of the deionizer must be free of any ions in the water, so the water from this step passes through the activated resin cartridges and finally the remaining 5% of the ions are removed.

Final water purification

In order to remove all the micro-organisms and germs and viruses in the water, it’s necessary to emit ultraviolet rays to it. At this stage, the TOC index of water reaches 5 to 10ppb. Then the water passing through the UF membrane and purifying by ultrafiltration and microfiltration, any charged enzymes and germs are removed. The water produced in the last step from the deionizer is known as hungry water, which is mostly used in medical and laboratory applications.

Uses of Deionizer

Due to the process of water purification in the deionizer and the very high purity in the output of this device, as a result, it can be used in various industrial and medical applications. Among the uses of the ionizer are:

· Distilled water

· Serum production

· Medical industry for example blood dialysis machine

· Washing dishes and laboratory equipment

· Using in HPLC tests

· Electroplating industries

· Paint factories

· Washing electronic components and boards

· Pharmaceutical factories

· Health and food factories and all pharmaceutical industries

Benefits of deionizer water treatment

· Production of high purity ion-free water (more than 99%)

· Long lasting filters

· Low price

· No effluent production

· Low power consumption

Important points about the production of pure water with a deionizer

Deionized water produced by the deionizer is known as hungry water. Therefore, it’s highly susceptible to the absorption of microbes and pollutants in the environment and carbon dioxide. By reabsorbing these substances, the purity of water is greatly reduced and it is less used for medical purposes. That is why the pure water produced by this device should be used immediately.

In addition, the resins of the device need to be charged and regenerated after prolonged use. The process of charging resins is such that the cationic column is placed in acids such as sulfuric acid and hydrochloric acid. In contrast, the anionic column resin charge of the deionizer will be immersed in hydroxide.

Production of deionizer in Haft Industrial Group

Due to the very wide application of deionizer in medical, pharmaceutical and health and food materials and very high sensitivity in the design and production of this device, “Haft Industrial Group” with years of experience and production expertise, has placed this device in its service group. All stages of design and production of deionizer in this collection have been done by experienced specialists and engineers, and reasonable price and high efficiency are its main features. In order to receive advice and guidance, as well as to buy a deionizer from Haft Industrial Group, you can use the communication channels at the bottom of the page.