Flocculant package (preparation package and injection of polyelectrolyte or polyacrylamide) is one of the most important equipment in wastewater treatment, which is based on the use of polymers in flocculation of suspended solids. The efficiency of this package is very high compared to other methods of flocculation of suspended solids and therefore it is used in various industries. Haft Industrial Group; It is the manufacturer of flocculant package and will answer questions such as how flocculant package works, what are the components of polyelectrolyte package and what standards are considered in designing, manufacturing and producing flocculant package.

What is a flocculant package? (Polyelectrolyte preparation and injection package)

The presence of suspended solids in water with like charges is one of the biggest problems in water treatment systems, which ultimately damage the internal equipment of the device and lead to reduced water quality. Due to the molecular structure of polymers and the creation of negative and positive charges or neutralization of the ambience, this property has been used in the design and fabrication of the flocculant package. In other words, a polyelectrolyte or polyacrylamide injection package includes a set of activities such as injecting a polymer into water and creating positive and negative charges in water. Due to the fact that suspended particles in water have positive or negative like charges, as a result, it is not possible for them to settle to the bottom of the water. By designing and making flocculant, in fact, by injecting polyelectrolyte, the ambience becomes charged and causes particles to be attracted to each other. The cohesive particles eventually settle to the bottom of the machine due to their heavy weight.

Types of flocculation

Flocculants or polyelectrolyte injections are divided into three groups according to the type of material and powder that dissolve in water, which are:

Cationic flocculant

Particles suspended in water generally have a positive or negative charge, and by injecting polyelectric cationic powders, positive charges are created in the water. The positive charge or cation created in the water absorbs the negative particles and creates clots on the water and finally they are transferred to the bottom of the device.

Anionic polyelectrolyte

Anionic flocculants, also known as anionic polyelectrolytes, cause negative charges by injecting polymer powder into water. Like the cationic type, the negative charges of the medium eventually cause the positively charged particles to clot and settle over time after condensation.

Of course, it should be noted that creating a negative or positive charge in the ambience in the first stage depends on what powder is used in the device after designing the flocculant package. As a result, it can be said that according to the powder and polymer that is injected in water, flocculant can be divided into groups of bioflocculant, cationic polyacrylamide type two and three, diallyl dimethyl chloride, bonded flocculant, cationic polyethylene amine.

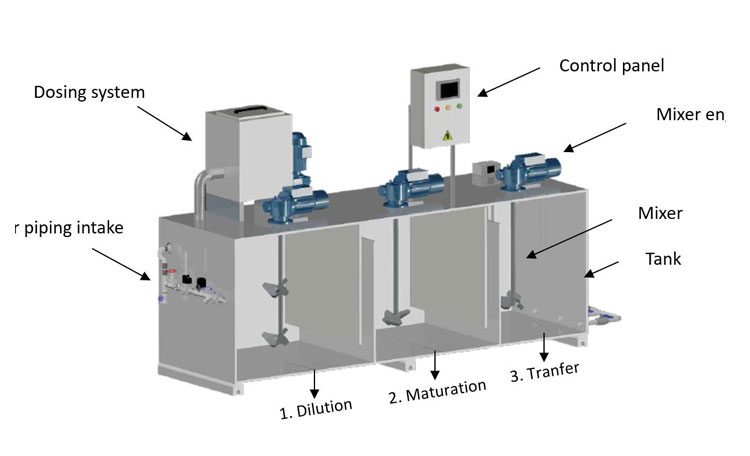

Polyelectrolyte injection package components

· In the design and production of the flocculant package and according to the application of the device, various components are considered for it. In general, the main components used in the design of the polyelectric package can be mentioned as follows:

· Special container for placing polyelectrolyte powder

· Flocculant powder or liquid injection system

· Stir and mix tank

· Preparation and dilution tank

· The main tank

· Pipping

· Alarm system

· Plc

· Dosing pump

Flocculant pump is one of the most important components of the polyelectrolyte preparation and injection package, which is used in two types, mono and extrinsic. Flocculant pump is used in large and industrial wastewater treatment systems to prevent high water hardness.

Flocculant package design

The design of the flocculant package should be done according to international standards due to its great impact on water quality in industrial and even drinking applications. In designing the polyelectrolyte package, the industrial group has considered seven different capacities for its tank. The capacities provided for this equipment are in accordance with the place of installation and use and will vary according to the type of order. In general, in the design and production of flocculant, three powder tanks, injection and main tank are used, all of which have impact and corrosion resistant bodies. It should also be noted that the resistance of other parts and components of the polyelectrolyte preparation and injection package is also considered in all design stages.

Making flocculant

Haft Industrial Group is one of the largest manufacturers of water and wastewater treatment equipment, which has included the production of flocculant package in its activities in order to flocculate and separate suspended particles in water. The construction of flocculant package in this complex has been done by professional and experienced engineers and is in accordance with international standards. For information about the specifications considered in the manufacture of flocculants in Haft Industrial Group, you can contact the experts of this collection and receive the necessary instructions before purchasing the flocculant package

Flocculant price

The price of flocculant in the first stage depends on the capacity of its tanks and therefore it is not possible to provide a specific rate for this equipment in this article. In addition, the material of the body and the type of internal parts and components also affect the price of the flocculation package. To inquire about the price of polyelectrolyte, you can use the communication channels mentioned at the bottom of the page.

How flocculant package works

As mentioned at the beginning of the text, 1 micron micro particles in water have like charges and are therefore scattered and suspended in the water. The operation of the polyelectric package is that first the polymer powder with alkaline or acidic properties is injected into the water and after the reactions, a cationic or anionic ambience is created. Creating a positive or negative charge leads to the creation of van der Waals force, which eventually leads to the adhesion of suspended particles and clotting. Suspended flocculants, called flocs, settle at different speeds depending on their weight. Of course, it should be noted that in some cases, due to the weight of the flocs and the conditions in the tank, it may be necessary to create a centrifugal force or to thicken the ambience. After thickening, the clotted material settles to the bottom of a tank called a Thickener and is drained from the bottom. The output of this set of processes will be clear water and used in various industries.

Application of polyelectrolyte package

- The most important applications of the polyelectrolyte package include the following:· Water clarification with the process of flocculation of suspended particles in the industrial treatment plant· Removal of solid particles suspended in drinking water in treatment plants· Use of flocculant package in refineries and petrochemical industries and removal of colloids from paint

· By increasing the water absorption coefficient and improving agricultural water

· Use of flocculant in steel industry