Grit Classifiers are one of the most practical equipment for separating sand, gravel and fine solid particles in water, which helps a lot in wastewater treatment. The structure used in the design and construction of Grit Classifiers provides the ability for this equipment to remove sand up to 95% of water. Seven Industrial Group; The manufacturer of Grit Classifiers for wastewater treatment will provide everything you need to know about the important points in the design of Grit Classifiers, how it works and its price.

What are Grit Classifiers?

Grit classifier is one of the most important and at the same time the simplest equipment for removing solids and fine particles in water. This device is used in various industries and can be considered one of the best options for grit chambers and drinking water treatment. One of the main reasons for using Grit Classifiers for wastewater treatment is to prevent damage to the pump and other parts of the purifiers. This is why Grit Classifiers are often used in the pre-treatment stage of wastewater.

How Grit classifier works

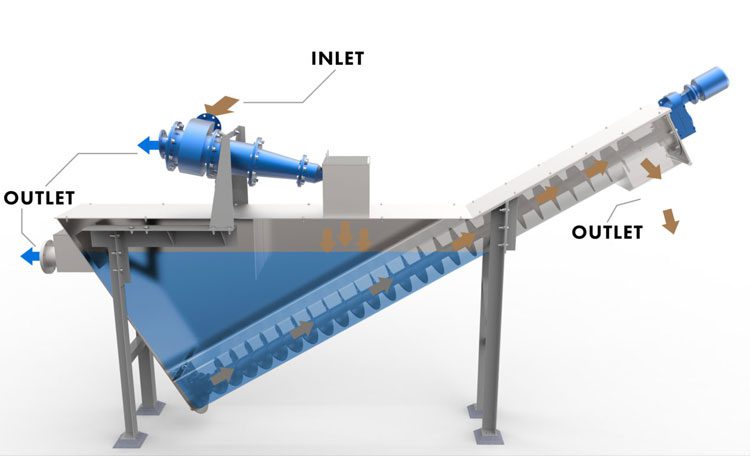

· In the structure intended for designing Grit classifier, several main parts are used, which are:

· Grit classifier body made of carbon steel and completely insulated against moisture, temperature and impact

· Screw conveyor to create centrifugal force

· Electro-gearbox

In general, how the Grit classifier works includes the following steps:

· Water enters the body of the device through the inlet valve.

· The current of the screw conveyor inside the body of the machine causes the belt to move and a centrifugal force is created

· Fine particles and grains of sand are separated from the water due to the movement of the conveyor and move to the outlet of the machine and come out of it.

· Water without sand and granular organic matter is prepared for consumption in the desired environments.

Grit classifier design

As mentioned, the design of the Grit classifier is based on the creation of centrifugal force inside the body of the device. With the help of this design method, energy consumption can be greatly saved and the efficiency of the device can be increased. In most Grit classifier devices, the efficiency is above 95%. A very important issue that is considered in the design of the classifier is the material used in different parts and components of the device. All parts in this device are made of carbon steel and have high resistance to corrosion and decay.

Production and manufacture of grit classifier

The use of grit classifier is used in various industries and its use is very important in extending the life of other wastewater treatment equipment. For this reason, Seven Industrial Group has included the production and manufacture of grit classifier wastewater treatment in its activities. It should be noted that all stages of design and production of grit classifier in this collection are done by professional and experienced engineers and are performed according to international standards. If you need to know the specifications of this equipment, you can contact the experts of Seven Industrial Group through the contact numbers mentioned at the bottom of the page.

Grit classifier price

The price of grit classifier, like other industrial and semi-industrial devices, does not have a specific rate and is determined based on several factors. Material used in the body and other parts of the grit classifier, its size and dimensions and capacity are among the factors that affect the price of the classifier. To inquire about the price of the classifier, you can contact Seven Industrial Group

Application of grit classifier

The presence of solids and fine grains such as sand in water is one of the biggest limitations in various industrial equipment that causes serious damage to their parts. Therefore, the removal of grains and sand is done by various methods such as grit classifier. Among the applications of the grit classifier, the following options can be mentioned:

· Removal of sand in drinking water treatment

· Removal of fine grains in water in the pre-treatment stage of wastewater in order to prevent damage to the pump and other parts

· Prevent salt deposition and clogged pipes

· Increase the working efficiency of clarifier and aeration equipment

Advantages of grit classifier

In addition to the good performance and the great impact that the grit classifier has on water quality, there are other reasons that affect the widespread use of this equipment, including:

· High resistance to temperature, humidity and impact due to the use of carbon steel in the manufacture of machine parts

· Easy to operate and use without previous experience

· Reducing energy consumption

· Low installation, maintenance and repair costs

· Ability to design and produce grit classifier in different sizes and capacities