Floating surface aerator is one of the most practical surface aeration systems that is designed and produced for municipal and industrial wastewater treatment. The basis of the work of this equipment and surface aeration system is to increase the contact surface of the wastewater with the air and to supply oxygen to the fluid in the treatment plant and to help treat it. Seven Industrial Group; The manufacturer of Floating surface aerator system has designed and produced this group of products in different sizes and models. In the following, we will provide a comprehensive guide including the introduction of the floating surface aerator system, important standards in the design, production and construction of Floating surface aerator and the price of its system.

What is a floating surface aerator?

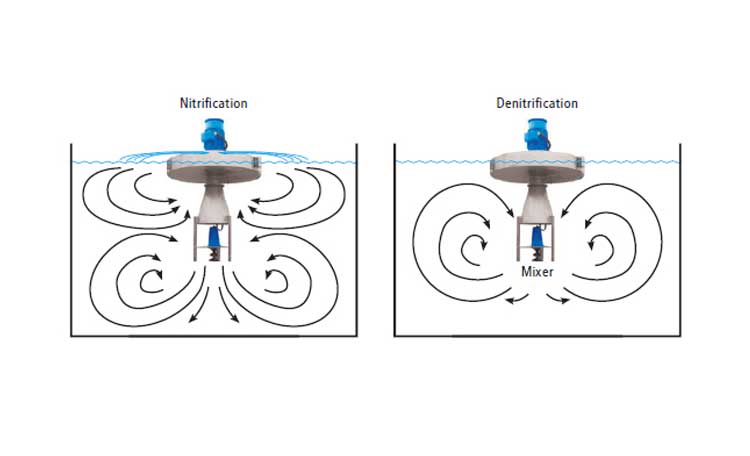

One of the most important steps in wastewater treatment with the help of activated sludge microorganisms is aeration and feeding of wastewater with oxygen in the air. For this purpose, aeration systems are used, which have different types that are divided into a general category of floating and fixed surface aeration. As the name implies, a floating surface aeration system is a set of equipment and components that cause the sewage to move and turbulence and make more contact with the air and transfer oxygen into the fluid. This type of surface sewage aeration system, by creating turbulence and suction, leads to the movement of sewage through conical pipes and their exit in a fountain and radial form.

How a sewage floating surface aeration system works?

To describe the operation of Surface Aerator systems, it is necessary to get acquainted with the various parts and components of this device. In the design and construction of floating surface aerators, several important parts and components have been considered, which are:

· Floating structures

· SSeven and impeller

· Conical pipe for sewage suction

· Electro-Motor

· Rain cap

Due to the use of floating structures in the design of surface aeration, this product has the ability to move on the surface of the treatment plant and in all parts leads to turbulence and mixing of wastewater with air. The impeller installed at the end of the device moves with the help of the force generated by the electric motor and causes suction in the conical tube. The impeller circumference is adjustable according to the conditions and its general shape is considered to be of the propeller type. After suction, the wastewater is transferred upwards from the conical pipe and is distributed radially around the marked pores. Turbulence and movement of sewage by moving the impeller and spreading it around through conical pipes greatly increases the contact of sewage with air. This contact with the air causes oxygen to be transferred into the treatment plant and aerobic bacteria to be fed and the purification process to be done better with activated sludge.

Floating surface aerator types

One of the most important differences in the design of sewage surface aeration system is the speed of rotation and correction around this equipment. Accordingly, in general, two types of floating aeration systems are produced, which are:

high speed surface aerator

The procedure for a high speed surface aerator is similar to that mentioned above. One of the most important features of this type of surface aeration system is that it does not need a gearbox to reduce the speed of the device, and therefore, the impeller is connected directly to the electromotor sSeven. In this type of aeration system, it is used for felt bowls or rain caps to prevent water and sewage from entering the coil.

Due to the very high power of high-speed floating aeration systems in creating turbulence and oxygenation of wastewater, it will be a good option for wastewater treatment in large and industrial treatment plants. In addition, it should be noted that due to the type of organic matter available in industrial wastewater, to prevent corrosion and decay of equipment and body, stainless steel and fiberglass are used to produce them.

low speed surface aerator

Another type of surface aeration system is the low speed surface aerator, the main feature of which is the use of a gearbox to move the impeller. As the name implies, the speed of rotation of the impeller and the turbulence created on the surface of the sewage is less than the fast type, and therefore it is mostly used to dissolve in sewage, aeration tanks and lagoons. In addition, its slow speed increases the life of the device and makes it easy to maintain.

Low speed surface aerator, like high speed surface, has the ability to design, install, use and maintain, and is widely used in various filters, and due to their body material, they are highly resistant to industrial organic materials and corrosive. It should be noted that both fast and slow aerators have tow ropes and can be fixed in the desired environment.

Floating surface aerator design

In designing a floating surface aerator, it is necessary to pay attention to several important issues, the most important of which is the body material of the device. Various organic and chemical substances present in industrial and sanitary wastewaters, eventually cause corrosion in water and wastewater treatment equipment. In order to extend the life of floating surface aeration systems, it is necessary to make their bodies from corrosion-resistant materials such as stainless steel and fiberglass. Other important factors in the design of floating surface aerator are the size, dimensions and speed of rotation of the motor and the lack of water penetration into the coil of the device.

Production and manufacture of floating surface aerators

Seven Industrial Group is one of the most experienced teams in the design and production of water treatment equipment, which, due to the important role of aeration systems, has put their production in its activities. All stages of design, production and construction of fast and slow floating surface aerators in this complex are performed under the supervision of experienced and professional engineers. To know the features of each of these products, the experts of Seven Industrial Group are ready to provide free advice before purchasing a floating surface aeration system through the communication channels at the bottom of the page.

Floating surface aerator price

The price of a floating surface aerator varies according to its type (fast or slow speed), body material, size and capacity of the device and brand of engine and other parts. We suggest that you contact Seven Industrial Group for information on the price of floating surface aerators.