Chemical injection package or chemical injection machine is one of the most widely used equipment in various industries, such as wastewater treatment. The purpose of designing and manufacturing a chemical injection package is to add solid or liquid chemicals to the fluid, which is done for a variety of reasons. seven Industrial Group; The manufacturer of the chemical injection package provides a comprehensive guide to get acquainted with this product, which includes the introduction of the package, its components, how the chemical injection machine works, the important principles and standards used in the design and production of the chemicals injection package.

What is a chemical injection package?

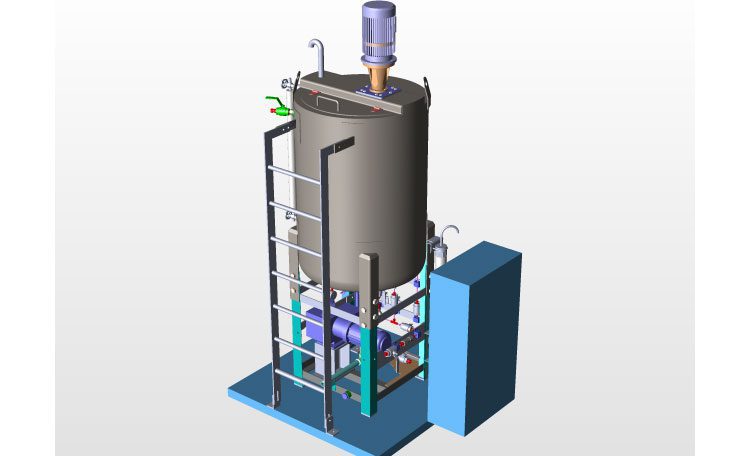

In various industries such as water treatment, industrial plants and refineries, adding various chemicals to descale, disinfect, separate suspended particles and clot them from water and other fluids is one of the most essential tasks. Chemical preparation and injection package is a set of several tanks, mixers and dosing pumps and fittings that prepare and add the desired chemicals for injection into the desired fluid. All steps of this work can be done automatically without the intervention of the operator, and as a result, the amount of added material is determined and injected quite accurately.

How the chemical injection package works?

The working steps of the chemical injection machine are generally divided into two parts, which include preparing the solution and injecting it. In the preparation of chemicals, first the desired powder or liquid enters the tank in which the mixer is located with adjustable speed. The desired material is mixed with water and enters the injection stage. To inject this solution, a dosing pump is provided that can inject the resulting solution in a certain amount into the next tank. One of the most important differences in the design of the chemical injection package is the way the dose of the injection pump is adjusted, which can be adjusted manually in some and fully automatic in others.

The general procedure of all injection machines is the same, and due to the capabilities provided for them, they may differ slightly in detail. For example, the injection device may be designed in such a way that after preparing the chemicals, the resulting solution enters another tank and is injected from there. But in some models of this device, it has two tanks and after preparation, it is added to the main tank in which the desired fluid is located.

Chemical injection package components

In designing and producing the chemical injection package, several important parts and sections are considered, which according to the model of the device, the desired capacity and also the type of injected materials, there may be differences in their selection and design. The main components of the chemical injection machine can be mentioned as follows:

Injection device tank

In the design of chemical preparation and injection machine, several tanks are considered, each of which has specific functions. The number of tanks of the device may be one or two, in the case of a single tank, the solution enters the storage environment of the desired fluid immediately after preparation, and in the case of two tanks, after the preparation stage; The solution enters the second tank and is injected from there. In any case, it is necessary for the tank of the chemical injection package to be completely resistant to contact with acidic substances, etc., and to prevent corrosion and decay in it over time. The material used for these tanks is often stainless steel, polyethylene and steel, which with epoxy coating have a high resistance to acidic and chemical substances.

Another difference in the design and construction of chemical injection machines is the capacity of their tanks. The capacity and size of the tanks are determined according to the place of their use and therefore there is a big difference between this group of injection machines.

Chemical injection pump (dosing pump)

Another very important and practical component of this package is the chemical injection pump. The dosing pump is responsible for injecting chemicals with a predetermined size and flow. Due to the fact that the injection pump is in contact with chemicals, it must be completely insulated and resistant to corrosion. Therefore, various parts and components such as washers and suction valves as well as pump heads, known as “wet head”, are made of durable materials such as PVC, polypropylene, PVDF, stainless steel and PTFF. The use of these materials in the design and construction of chemical injection pumps makes acidic and alkaline materials and chemical reactions with them do not cause corrosion, decay and damage in various parts of the pump.

The dosing of the injection pump can be adjusted manually and automatically, and its motor operates with the help of electrical, electromagnetic, pneumatic and hydraulic energy. Maintenance and repair of this part of the chemical injection machine is of the highest importance, and disruption in its work process and not injecting the required amount of material has many consequences.

Chemical injection machine control board

The control board, as its name implies, is responsible for commanding the injection pump. According to the capabilities considered during the design and production of the chemical injection package, the commands sent by this board are done manually and automatically.

Mixer or stirrer

In order to prepare chemicals for injection into a fluid, it must first be completely dissolved in water. These materials may be solid or liquid, which is completely dissolved in water with the help of a mixer with different speed and power and a homogeneous solution is obtained. This part of the device has other components such as motor, shaft, impeller, gearbox and coupling. Another difference between chemical preparation and injection devices is the power and range of the electromotor intended for its mixer, which is determined according to the capacity of the tank and the type of chemicals.

Instrumentation

In different industrial and semi-industrial environments, the amount of chemicals required may vary depending on the conditions in the tank and the condition of the fluid. For example, depending on the pH of the fluid, it may be necessary to change the pump flow or to inject the injection dose based on the temperature of the fluid.

For this purpose, in the design of chemical injection machine, high-precision measuring instruments, displaying or sending commands in different conditions are considered as precision instruments.

Chassis and drain valve are other components and accessories of the chemical injection system that the chassis is used to install and maintain the device and drain valve in order to remove the deposits created in the bottom of the tank.

Design of chemical injection machine

In order to increase the efficiency and effectiveness of the chemical injection system, it is necessary to consider several standards in its design process. For example, the capacity of the tank is one of the things that should be considered in the design of the device, which is determined based on the type of application and the required chemicals. The power and range of the mixer motor, the material used in different parts, the lifespan and efficiency of the precision and manual tools or the automatic process of adjusting the pump dose are among the items that should be considered in designing the chemical injection package. So that in the products produced by seven Industrial Group, the standardization of all parts and sections can be fully felt. The products of this collection have an automatic dosing pump adjustment system based on the current state of the fluid and its parts are made from the best European brands.

Construction of chemical injection system

seven Industrial Group is one of the largest manufacturers of injection systems in different sizes and capacities, which has several important principles in its activities. One of the most important principles that this collection considers in making the chemical injection package is to use the expertise and experience of professionals in this field, to use parts from the best brands in the world and to increase the efficiency and effectiveness of the device with accurate and standard design based on customer’s need. It should be noted that all stages of manufacturing the chemical injection package in seven Industrial Group are carried out under the supervision of fully professional and experienced engineers in the field. To know the features intended for each of the products in this collection, the experts of Seven Industrial Group; Provide the necessary advice and guidance before buying a chemical injection package.

Price of package for preparation and injection of chemicals

The price of chemical injection package depends on several factors, the most important of which are the number and capacity of tanks, power and range of mixer, brand of mixer motor, brand of injection pump, adjustable dosing pump (manual or automatic), type of instrument and The material used in the manufacture and production of various parts and equipment of the pointing device. To inquire about the price of the chemical injection package, you can use the communication channels mentioned at the bottom of the page and contact the experts of seven Industrial Group.

Application of chemical injection system

As mentioned, chemicals are injected into tanks in various industries for a variety of reasons. The main applications and reasons for using and buying chemical injection packages can be mentioned as follows:

· Injection of coagulants for flocculation of suspended particles in clarifier systems

· Prevent sediment in pipes and installations of boilers and heat exchangers

· Water and wastewater treatment by chlorine injection

· Injection of various chemicals in the food industry

· Injection of disinfectants in large and small water and wastewater treatment plants

· Injection of chemicals in the production line of factories

· Use of antiscalant injection package, well injection package, caustic soda injection package in oil and gas refineries